1-2 week possible wait for flasher tool for remote tuning.

Security policy

Delivery policy

Return policy

The automatic 8-speed gearbox of the acclaimed gear manufacturer from Friedrichshafen (Zahnradfabriek Friedrichshafen) is known as bulletproof and fast. First used in 2008. The ZF8HP automatic gearbox is now used by almost the entire automotive industry. From the BMW F20 116i with a maximum load of a few hp and 300 Nm to the Dodge Ram TRX with 6.2 supercharged engine with 707 hp and 900 Nm.

Of course Audi, Aston Martin, Jeep, Rolls Royce, Toyota and many other brands use the ZF8HP. Of course, Alfa Romeo has also opted for ZF for the Giulia and Stelvio. The 8HP50 and the 8HP75 are used in the 2.0T/2.2 JTDm and Q models. With a maximum load of 550 Nm for the JTDm and 500 Nm for the 2.0T, they offer plenty of room for tuning. The Q models allow 750 Nm.

Because the 8HP is used by so many manufacturers, the supplied software must also meet all the wishes of each manufacturer. Therefore, the software is prepared for many possible control strategies and applications.

BMW gearbox tuning has been on the market for some time after information was released. This made it possible to enter the control unit of the gearbox. Then it was only a matter of time before the market is overwhelmed with this form of tuning. The tuning possibilities for Alfa Romeo only came much later. Unfortunately, tuning via the OBD plug is not possible with Alfa Romeos, yet (we are working on it). Work must be done directly on the plug of the gearbox computer. The control unit is built into the gearbox. So we nust access it there.

That said, what what kind of tuning can be had with the software?

It should be noted that a gearbox is something completely different from an engine. Pretty much all our experience is engine tuning. We started with a blank sheet of paper with this. We now know “quite well” how an engine works. But how does an automatic gearbox actually work? Apart from the basic knowledge, we didn't know much about it. So let's dive into the books first. You can't work on the software without knowing how it really works.

Engine tuning is about turbo pressures, ignition or fuel quantities. With gearboxes, it is about disconnecting and coupling transmissions. The 8-speed has 5 clutches that are controlled by hydraulics. With those 5 couplings, 8 gears can be made. In addition to these clutches, there is also the torque converter (think of this as the clutch on a manual gearbox).

In terms of software, there are countless tables that show everything about internal oil pressure (hydraulics) and disconnect and torque pressures and times. Countless switchable strategies, reference tables. Certain tables apply to each gear change. Certain tables apply to each DNA position. Certain tables apply to the way in which people drive (acceleration, braking, lateral forces, uphill, downhill) etc. etc. In short, an endless list of tables

But it's a little different. In engine tuning we use a lot of diagnostic equipment with which we can read back almost every parameter. As a result, we know exactly what is happening and whether a software adjustment has the desired effect. Unfortunately, that turns out to be different with gearboxes. The available parameters are very limited at Alfa Romeo. Most provide no useful information. A lot must therefore become clear by driving it on public roads and close attention/ feeling what the gearbox does. Not even a wealth of information here either that offers a solution. The car is then stationary. So no acceleration and lateral forces.

Fortunately, we did have access to other very valuable information. We will not discuss this in detail here, after all, the competitors also will read this.

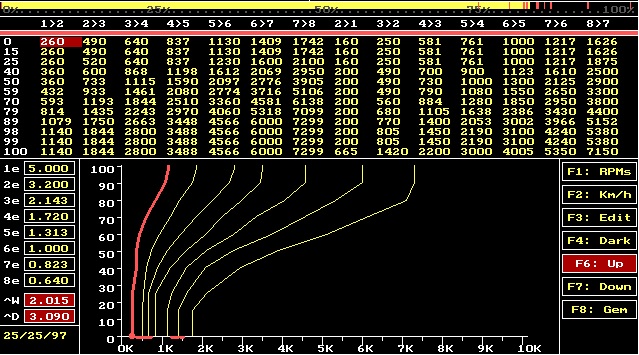

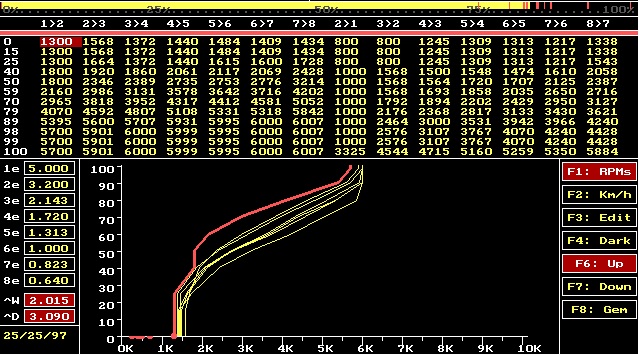

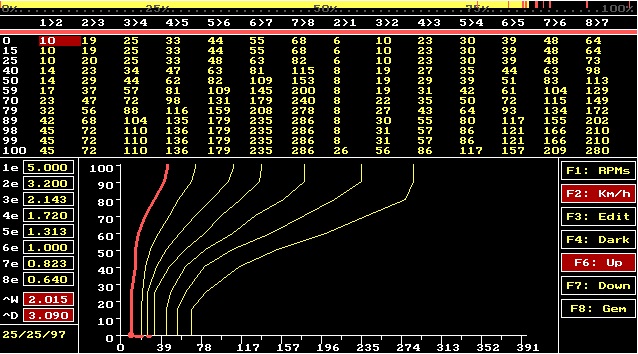

The software is equipped with an average of 100 different switching tables. These are the tables that show when upshifting or downshifting takes place. This shift point depends on the accelerator pedal position and the output speed of the gearbox. That last one alone is a tricky one. As a driver you have no idea about that. Do you know? What you as a driver has is the idea of the speed of the engine. This is indicated on the dashboard. In short, to make the switching tables more transparent, we had to have a conversion made in our own software, with which we develop our tuning software. Since we also made this software ourselves, that was under control. The pictures below show that.

Up and downshift moments expressed in output shaft speed (RPM)

Upshifts and downshifts expressed in vehicle speed (km/h/Mph)

But how do you find out which of the 100 switching tables is used under which circumstances? That was partly described by the additional information we had. But unfortunately that turned out not to be complete either, which ultimately comes down to a lot of trial & error and logical thinking. Eventually the various quarters will fall in-line by themselves.

But there are also nasty snags hidden under the grass. For example, there is an option in the software that allows you to suddenly use another switching table under certain circumstances. For example, when driving through the city at 50 km/h in Dynamic, the gearbox should continue to drive in 4 th gear according to the gear shift table to be followed. But this does not happen. It is still switched to 5th, which results in a speed that is too low in our opinion. We got hold of this snag and dealt with it.

Downshift Strategy

We think that there is still an unpleasantness in the downshifting strategy. When there is (really) hard braking, there is an extra amount of downshifting. This is sometimes accompanied by so much drama that people drive in too low a gear after the violent braking action. Then it takes a while before the tank is back to its positives and starts shifting again. We have weakened this strategy. There is still a sporty downshift, but not so exaggerated.

Switching Times

We are not going to make an attempt to make the gearbox faster switching times. We read everywhere that many “tuners” promise this. However, we also know that they work with certain information supplied. We have also studied that information and our conclusion is that this will not lead to faster switching times. It can, however, provide the feeling of faster switching times. Basically what they are trying to do is to increase the hydraulic pump pressure in the bucket. This would allow the couplings to move faster, but it will mainly ensure harder engagement moments of the coupling. That manifests itself in discomfort as far as we are concerned.

The real switching times are made up of many sub-actions. Every gear change of every gear of every DNA/R position has its own set of actions. This is so complex and precisely tuned that we have no illusions that we can improve it. So we don't.

Torque Limiters

The gearbox software is also equipped with torque limiters. However, with our Alfa's they are at such a high level that they are not a limiting factor even with good tuning. We have not yet come across any software where there is a limitation. But maybe we'll see them again. There are also torque limiters that come into effect when there is a malfunction or when the gearbox oil temperature rises too high. We do not adjust these. In our opinion, that is not wise.

The Absolute Rev Limiter

Raising the absolute rev limiter may be necessary if the rev limiter has been raised in the engine software. If the bucket limit is exceeded, this is accompanied by quite a dramatic effect. A literal hard run. Not pleasant. We increase this according to the needs of the engine tuning

Now, what is our gearbox tuning really all about?

We focus on switching moments in all DNA positions and eliminating inconveniences. Everything aimed at more experience and more driving pleasure.

Up and downshift moments expressed in output shaft speed (RPM)

Shift points of N moved to A

Shift points of D moved to N

Dynamic with milder Race Mode gear changes

Race completely unchanged

Increased maximum upshift speed (7250 RPM)

Elimination of upshifts around 50 km/h (31MPH)

Reduced downshifting under heavy braking

Stage 1 is intended for cars with Race Mode retrofitted. Normally the box shifts in Race just like in Dynamic. With Stage 1, we ensure that as soon as Race Mode is switched on, the gearbox also applies Race Mode shift points. That means continuing through the gears and downshifting earlier.

Stage 2 is intended for people who do not want Race Mode, but want more dynamic shifting behavior in the A, N and D modes.

Stage 3 = Stage 1 and Stage 2 combined.

How does this manifest itself in real life?

Engine tuning generally means more torque and power. Everyone can imagine something about that. It will provide faster acceleration.

However, we have noticed that it is difficult to imagine something with our gearbox tuning. As indicated earlier, we focus on changed switching times. This can best be described with the word “eager”. The car responds more quickly to accelerator pedal movements. The car doesn’t feel so lazy anymore.

One can also look at it differently. Suppose you drive in Dynamic. That already drives quite eagerly (if one doesn’t know any better). You then switch to the A position. The car feels noticeably lazier and more sluggish. Approximately the same difference is added to the Dynamic after the gearbox tuning. This is also noticeable when switching back from the new Dynamic to the N position. The N position has become the old Dynamic. The new N-mode/old D-mode suddenly feels lazy/slazy again. Strange but true.

We have also realized that people are often inclined to give a lot of gas when a lot of acceleration is required. This is somewhat logical because one wants to encourage the gearbox to downshift (kick down). After tuning, the need is much less because the driver now almost always drives one gear lower than before. The result is that the torque at the wheels is now higher than before. It is therefore not necessary to downshift. The car accelerates more easily. It is therefore no longer necessary to give a lot of gas. One now has to let the gearbox do the work and not so much the engine.

Results: